As is often the case, my projects require tools that are simply not available to the average

hobbyist. In these cases, the only choice is to build those tools as well. Often this is a

dealbreaker. But often the building of the tool is a fun project in itself. This project is a tool

that I needed in order to design and build my fully

autonomous filming drone. That project can be

seen here. The reason for needing this tool is a common pet peeve of mine; manufacturers do not

publish adequate specifications with their products. This is especially true of RC motors and

propellers. They are sold in standard sizes. But no performance data is ever given. In order to

truly engineer and design a custom quad copter from the ground up. I needed full torque, rpm, and

power curves of motors, as well as torque, rpm, and thrust data for propellers. The only way to get this

info was to measure it myself.

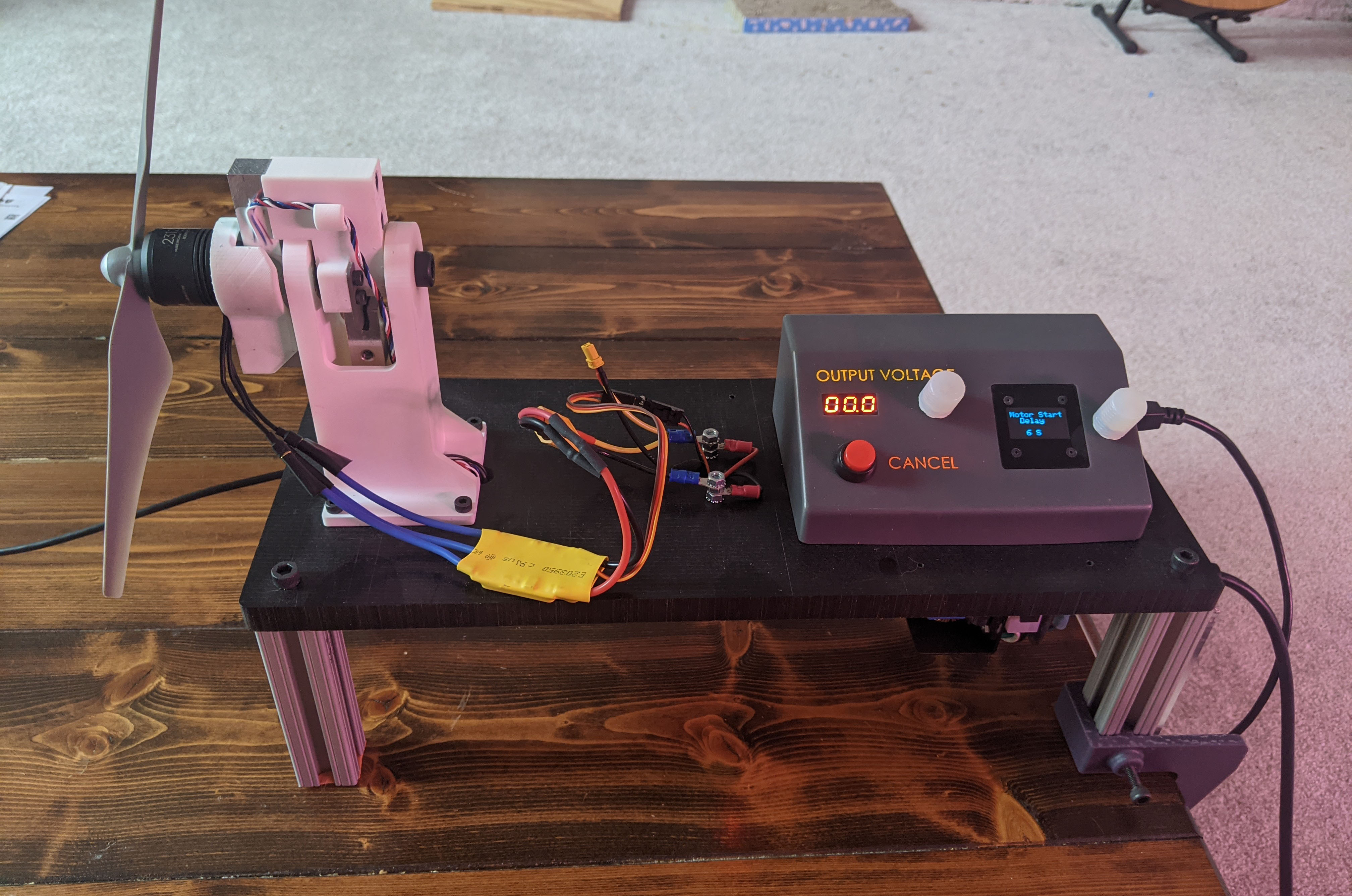

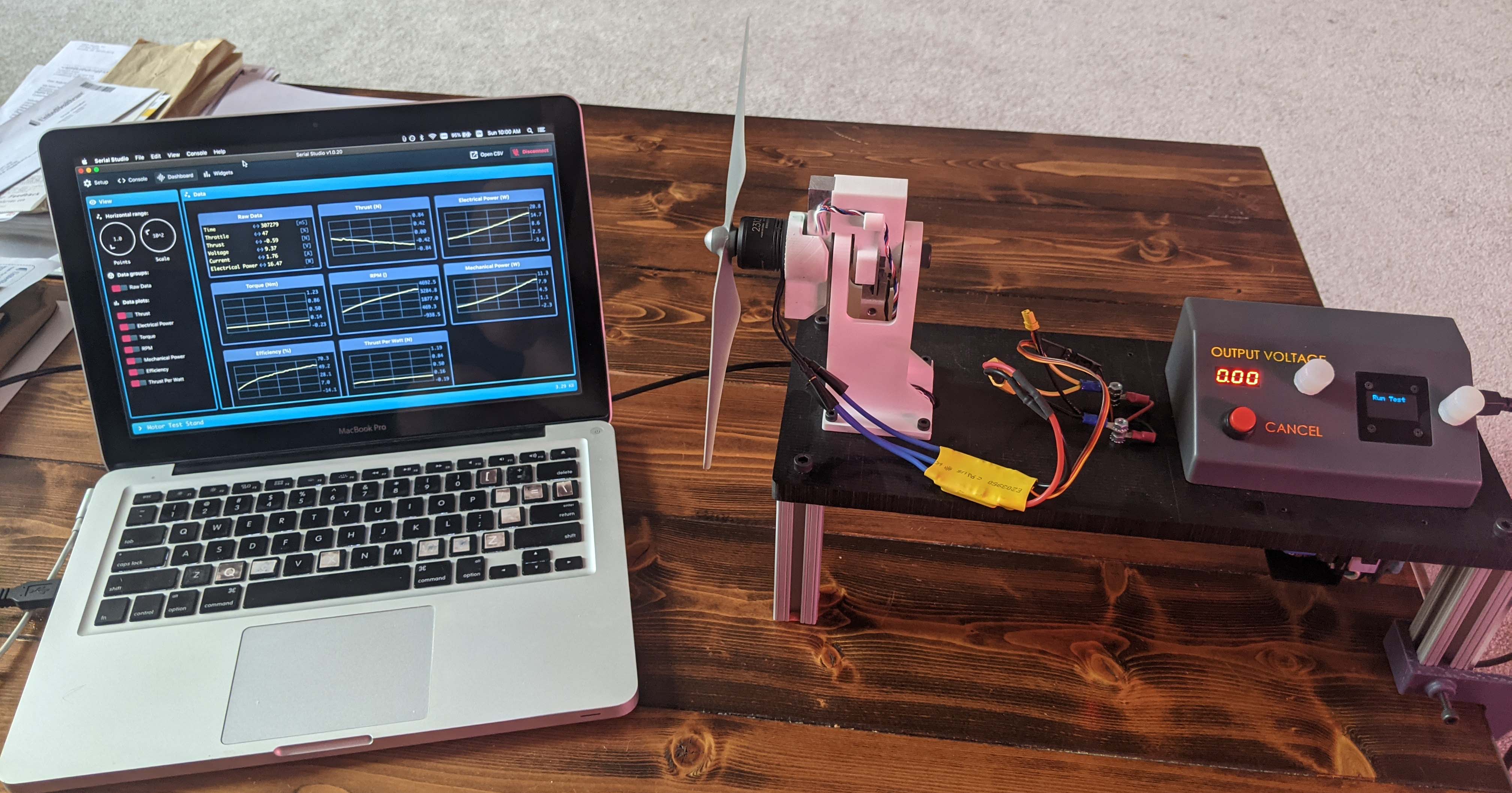

The device is capable of measuring torque, RPM, thrust, current, and voltage. By combining these

data in different ways, efficiency, specific thrust, torque curves, and thrust curves can be

generated that fully specify the performance of motors and propellers.

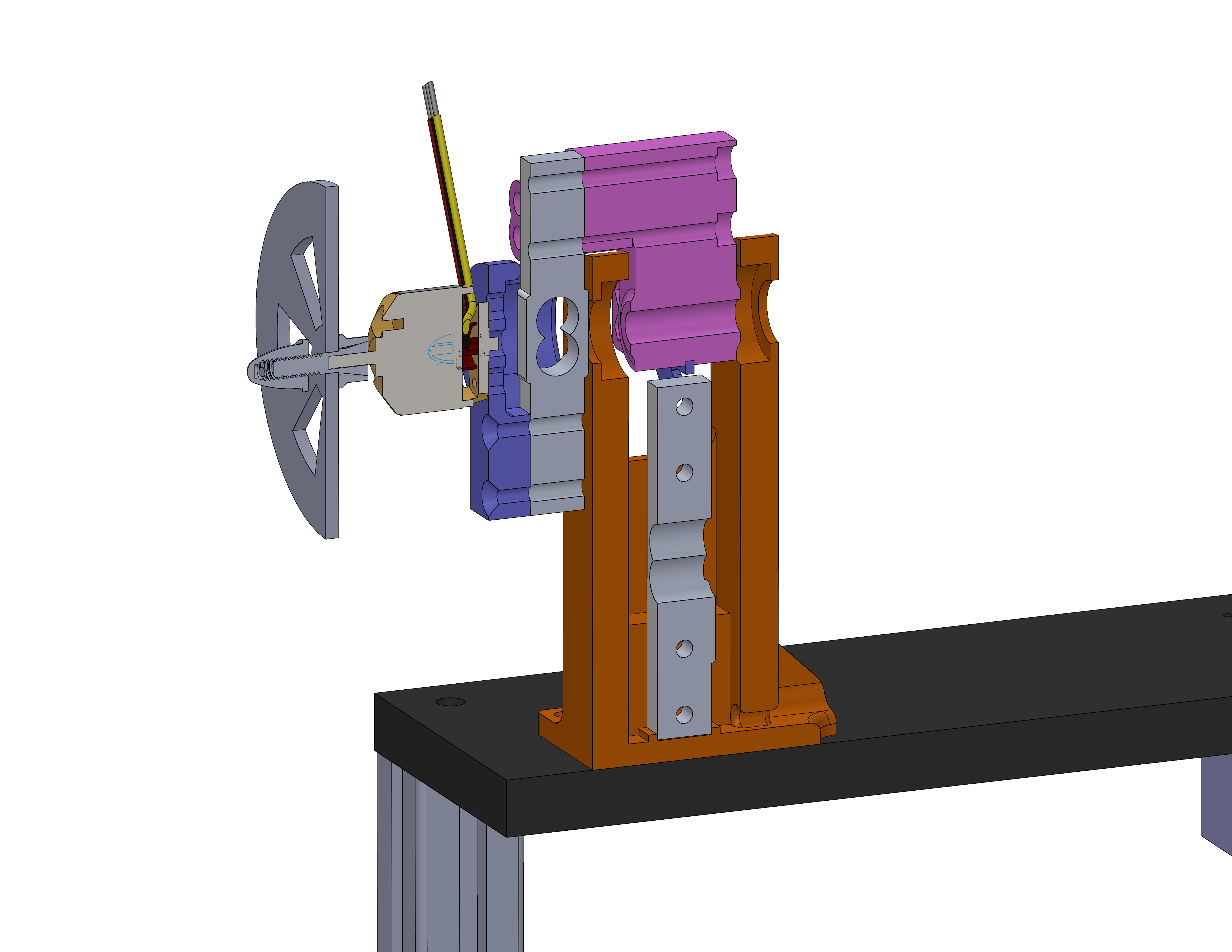

Two load cells are used to measure torque and thrust. They assemble into 3D printed parts that house

bearings and a mount for the motor under test. HX711 breakout boards measure the load cell voltage

and communicate with a microcontroller. A photodiode is also mounted close to the motor axis. The

fluctuations from the light passing through a spinning propeller are measured, and the RPM is

calculated. 3D printed feet hooks at the back allow the device to be used on a table top without

being clamped down.

Two load cells are used to measure torque and thrust. They assemble into 3D printed parts that house

bearings and a mount for the motor under test. HX711 breakout boards measure the load cell voltage

and communicate with a microcontroller. A photodiode is also mounted close to the motor axis. The

fluctuations from the light passing through a spinning propeller are measured, and the RPM is

calculated. 3D printed feet hooks at the back allow the device to be used on a table top without

being clamped down.

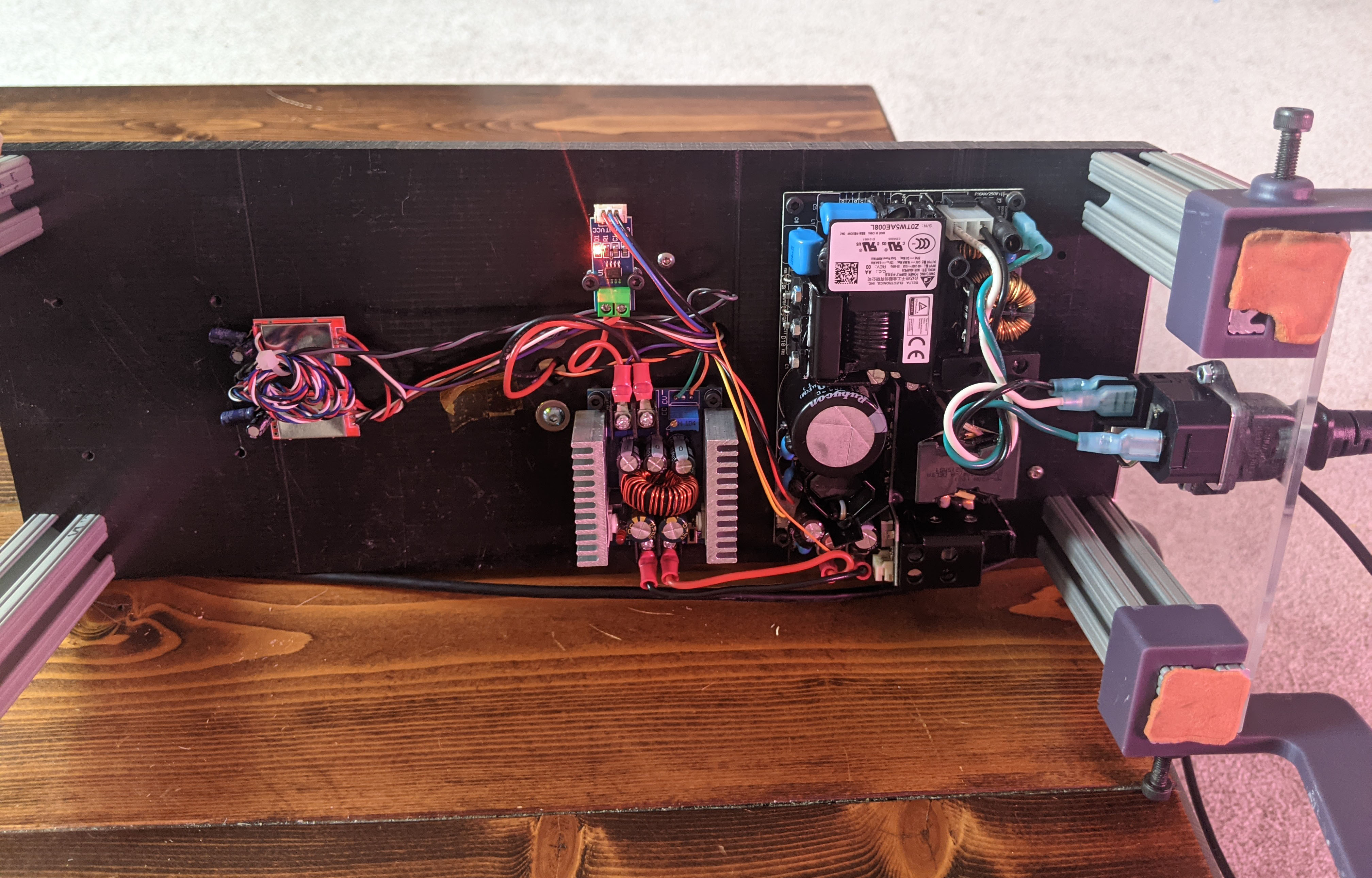

A 20 A hall effect current sensor is used along with a variable buck/boost converter to measure and

control the output voltage and current. A nice 3D printed housing encloses a potentiometer to

control the output voltage, an encoder to navigate the LCD menus, and a back/cancel button. Through

the LCD menus you can change settings such as number of blades on the propeller, the number of

points to record in auto test mode, max current, and max electrical power to prevent burning out

your motor.

A 20 A hall effect current sensor is used along with a variable buck/boost converter to measure and

control the output voltage and current. A nice 3D printed housing encloses a potentiometer to

control the output voltage, an encoder to navigate the LCD menus, and a back/cancel button. Through

the LCD menus you can change settings such as number of blades on the propeller, the number of

points to record in auto test mode, max current, and max electrical power to prevent burning out

your motor.

The device can be used in manual mode, the knob controlling the throttle, but the device can also be

used in auto mode. In this mode, the throttle is swept at the specified speed until an end condition

is met (such as max power, max throttle, thrust, etc). The values are sent over USB serial where the

values can be visualized and recorded. Additionally, peak values are recorded at all times including

all other measurement values that occurred at the peak. For example this not only allows recording

what the peak efficiency is, but it records what the current, voltage, rpm, thrust, ect. all were

when peak efficiency occurred.

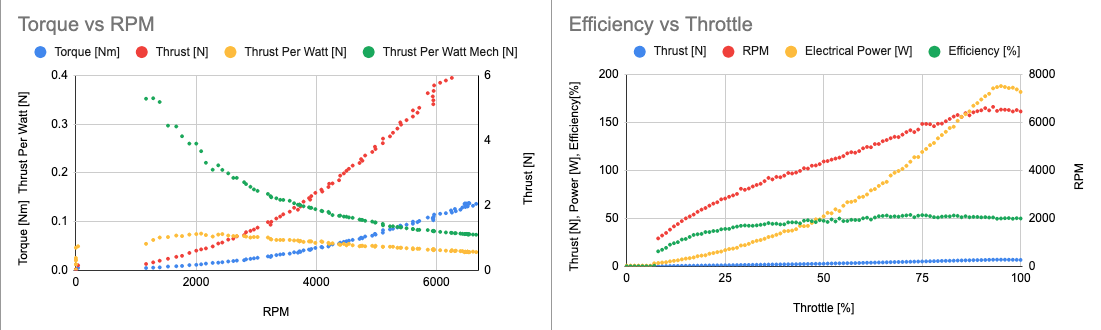

A custom program on my laptop reads the values sent over serial, and graphs them in real time as

well as writes them to a CSV File. These data can then be added to a spreadsheet for further

analysis.

The device can be used in manual mode, the knob controlling the throttle, but the device can also be

used in auto mode. In this mode, the throttle is swept at the specified speed until an end condition

is met (such as max power, max throttle, thrust, etc). The values are sent over USB serial where the

values can be visualized and recorded. Additionally, peak values are recorded at all times including

all other measurement values that occurred at the peak. For example this not only allows recording

what the peak efficiency is, but it records what the current, voltage, rpm, thrust, ect. all were

when peak efficiency occurred.

A custom program on my laptop reads the values sent over serial, and graphs them in real time as

well as writes them to a CSV File. These data can then be added to a spreadsheet for further

analysis.

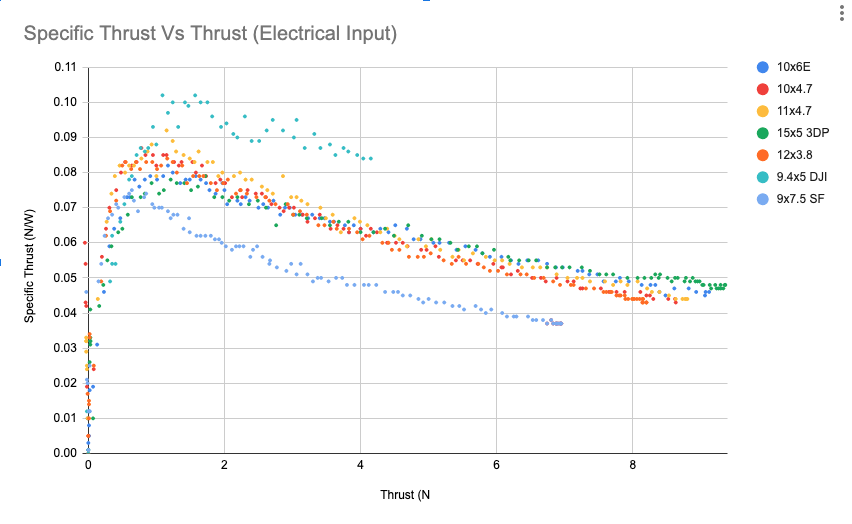

Over the course of designing my autonomous drone, I tested many propellers and motors. A comparison of some

propellers can be seen below. This shows the specific thrust (thrust per input power) vs

thrust. Essentially showing how good the propeller is at turning power into thrust. Below that, you

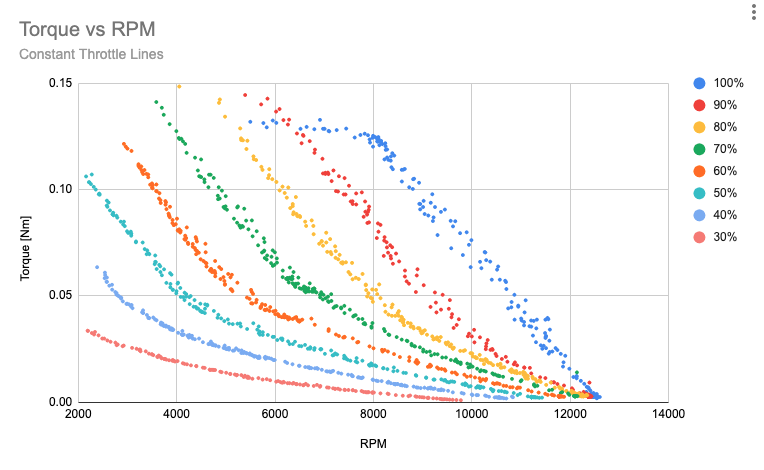

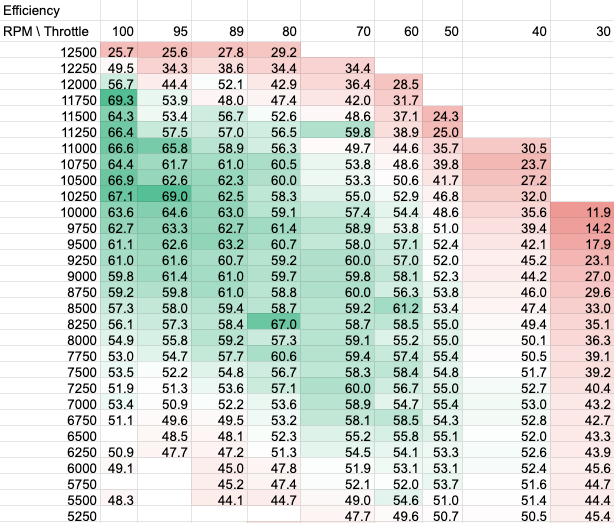

can see a motor torque curve chart at constant throttle values and a heat map of a motor efficiency.

The color indicates the motors efficiency. The x and y

axis represent the motors RPM and throttle. In this case you can see that the motor operates most

efficiently at about 80% of its unloaded RPM, at relatively high throttle settings. Although this

chart is for one input voltage, I also measured across a range of voltage to create a 4D plot. This

is needed for my custom drone because I cannot expect the battery voltage to remain constant as it

drains.

Over the course of designing my autonomous drone, I tested many propellers and motors. A comparison of some

propellers can be seen below. This shows the specific thrust (thrust per input power) vs

thrust. Essentially showing how good the propeller is at turning power into thrust. Below that, you

can see a motor torque curve chart at constant throttle values and a heat map of a motor efficiency.

The color indicates the motors efficiency. The x and y

axis represent the motors RPM and throttle. In this case you can see that the motor operates most

efficiently at about 80% of its unloaded RPM, at relatively high throttle settings. Although this

chart is for one input voltage, I also measured across a range of voltage to create a 4D plot. This

is needed for my custom drone because I cannot expect the battery voltage to remain constant as it

drains.

I’m super pleased at how well this device turned out. It greatly outperforms all hobby grade thrust

stands in both capabilities, accuracy, and resolution. This can handle motors with thrust from

fractions of a gram up to kilograms. It can measure RPM from 1000 to 50,000 blades per minute. And

can measure both mechanical and electrical power up to 280 Watts with a resolution of better than 50

mW.

I’m super pleased at how well this device turned out. It greatly outperforms all hobby grade thrust

stands in both capabilities, accuracy, and resolution. This can handle motors with thrust from

fractions of a gram up to kilograms. It can measure RPM from 1000 to 50,000 blades per minute. And

can measure both mechanical and electrical power up to 280 Watts with a resolution of better than 50

mW.