This is one of those projects that most people would say is impossible without lots of money or

expensive specialty tools. But I'm quite proud of how well I was able to get it to work, given

that it is made almost entirely from scrap parts.

If you are not familiar with EDM, it is a machining process that uses extremely rapid and hot arcs

to slowly vaporize and erode a conductive material away into a desired shape. Due to the extreme

current, speeds, and voltages involved, it is often regarded as a highly specialized process, reserved

for only extreme circumstances. Indeed, a commercial EDM machine can cost a few hundred thousand

dollars on the low end to millions on the high end. They can hold unbelievably tight tolerances due

to the fact that almost no force is applied to the material while machining. This does also require

extremely well regulated temperatures, and a fancy water filtration system, which I don't have. But

you can see an example of what is possible below. The letters are cut about half an inch deep into

a solid steel block using a tool of the inverse shape made from pure copper.

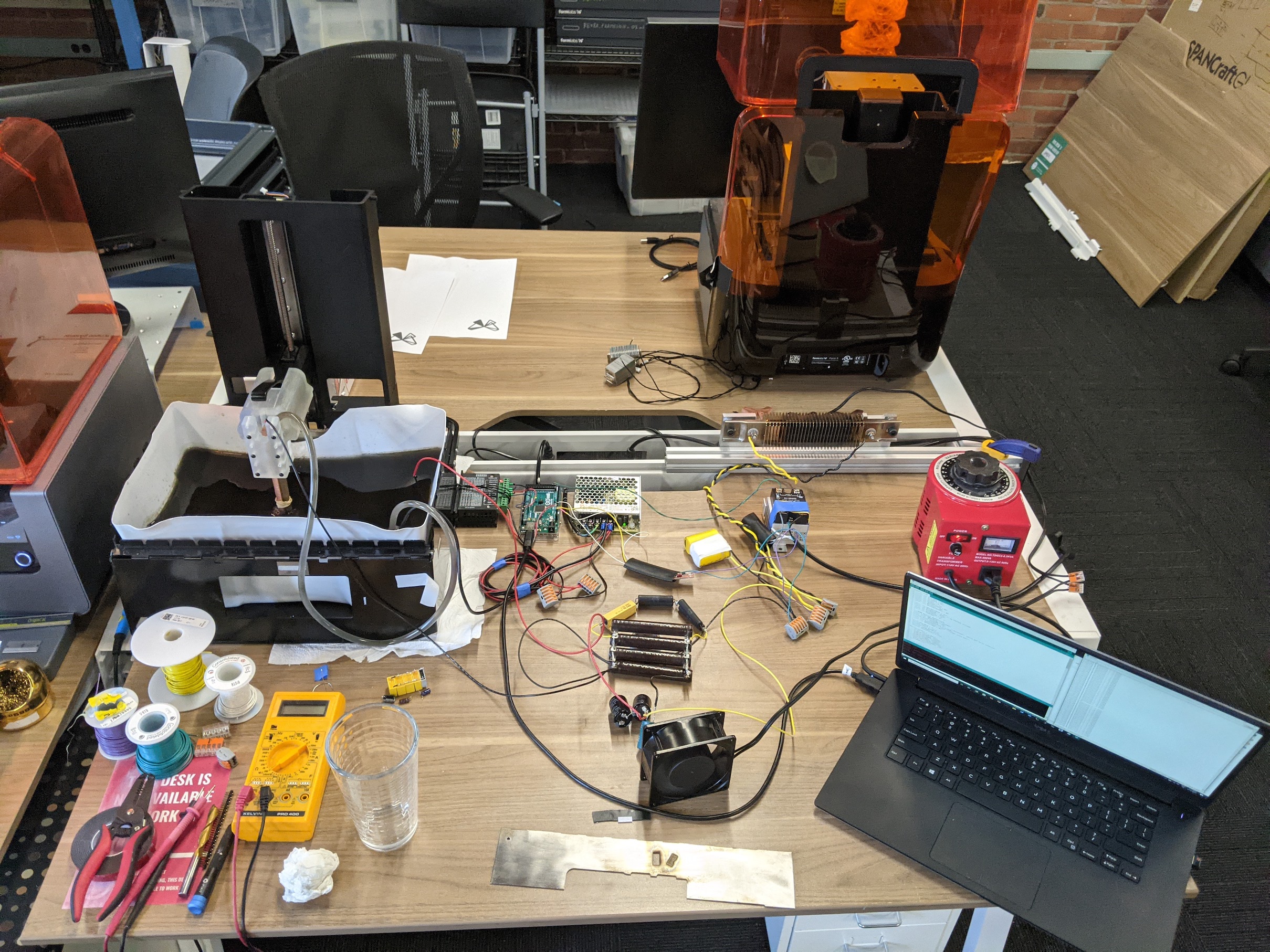

The machine that I made is based around the skeleton and Z axis of a retired SLA 3D printer.

A thermoformed tub holds the piece being machined, and the Z axis holds the tool that does

the cutting. An arduino monitors and controls the voltage in a capacitor bank, and moves the

tool closer and farther from the work, less than a micron at a time, to control the speed and

properties of the arc.

The machine that I made is based around the skeleton and Z axis of a retired SLA 3D printer.

A thermoformed tub holds the piece being machined, and the Z axis holds the tool that does

the cutting. An arduino monitors and controls the voltage in a capacitor bank, and moves the

tool closer and farther from the work, less than a micron at a time, to control the speed and

properties of the arc.

Another advantage of the EDM process is that it can cut any conductive material. Even materials

such as tungsten carbide, that traditionally can't be machined because they are so hard, can be

machined just as easily as tin or aluminum. You can see an example of this below. In just a few

minutes I was able to machine a large chunk out the the shank of a tungsten carbide end mill.

Another advantage of the EDM process is that it can cut any conductive material. Even materials

such as tungsten carbide, that traditionally can't be machined because they are so hard, can be

machined just as easily as tin or aluminum. You can see an example of this below. In just a few

minutes I was able to machine a large chunk out the the shank of a tungsten carbide end mill.

To see the EDM in action, including all the glorious sparks and noises, check out the

video below.

To see the EDM in action, including all the glorious sparks and noises, check out the

video below.