After the construction of my fourth potato gun, I immediately started designing another, bigger and better

gun. I knew I wanted this one to be pneumatic, and run off of compressed air. My ultimate goal is to design

a gun which will perform so well I can not (with my present capabilities) build a better gun. I wanted to

design it to achieve the highest muzzle velocity possible. I also wanted it to be as easy as possible to

use, load, and fire. And I wanted to design the shape so as not to be cumbersome or awkward (ha, good joke).

After the construction of my fourth potato gun, I immediately started designing another, bigger and better

gun. I knew I wanted this one to be pneumatic, and run off of compressed air. My ultimate goal is to design

a gun which will perform so well I can not (with my present capabilities) build a better gun. I wanted to

design it to achieve the highest muzzle velocity possible. I also wanted it to be as easy as possible to

use, load, and fire. And I wanted to design the shape so as not to be cumbersome or awkward (ha, good joke).

I found a video on Youtube around the time of my second potato gun, and just recently took the time to find

it again. In this video I saw the best potato gun I had found so far. It could shoot tennis balls at almost

500 miles per hour through pieces of 1/2-inch plywood and 3/4-inch particle board. I knew I would base my

gun on that one, but I would need to give it some improvements - - of course!

The final design that I settled on should theoretically be able to shoot a tennis ball close to the speed of

sound. In practice this is very difficult to achieve with compressed air only. The limiting factor is that

the compressed air itself doesn’t like to expand faster than the speed of sound. The speed at which the air

can rush into the barrel becomes choked, where the velocity is limited by the local speed of sound. At this

point, the flow rate of air can't be increased by lowering the downstream pressure, only by increasing the

density of the air i.e. increasing the upstream pressure. because the onyl practical material for this potato

gun is PVC, the pressure is limited by the pressure rating of the PVC pipe used.

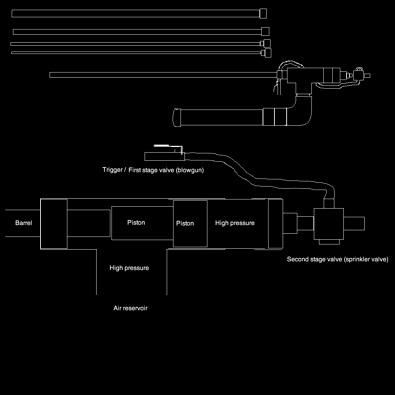

The body of my gun is made all from three-inch PVC. Above is a cross section. The gun uses a barrel sealing piston

valve. The design is optimized to open extremely quickly, applying the full air pressure behind the projectile

before it's had a chance to accelerate very far. It works by using some of the air inside the tank to force a

piston against the barrel. A primary stage valve vents the air pressure from behind the piston, which then slams

backward, opening the breech.

I had some problems building the gun; the rubber o-rings which I made out two shower drain gaskets, started

to decompose due to the petroleum jelly I used for lubricant. I also had to drill a small hole through the

piston. I was surprised that my homemade o-rings sealed as well as they did.

Left is a picture of the piston before I replaced the gaskets. So far the piston works wonderfully.

Unfortunately I have yet to try out this potato gun at its full power (I now live in the big city, where

there are limited venues for potato gun launches). Dry shots appear to work well though. Although it takes a

while, I have managed to pressurize it to 20 psi using a bike pump. Even at this pressure, just the air from

the breech will shred a piece of newspaper held within a few inches. Below is a picture of the finished gun

without a barrel and with a shorter-than-ideal air tank. Just this part of it weighs almost 12 pounds.